What is carbon fiber fabric?

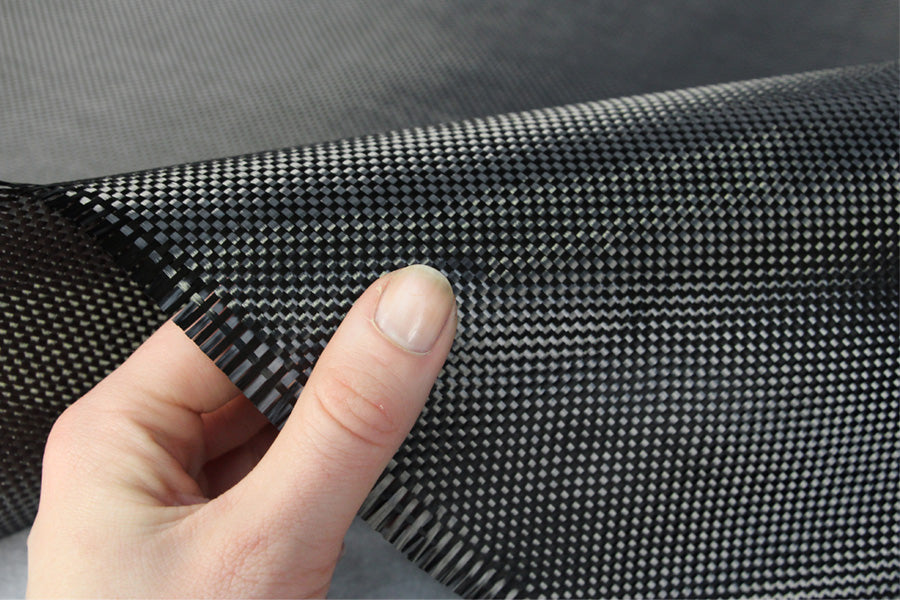

Carbon fiber cloth is composed of very thin carbon filaments that resemble super-strong yarn when twisted together into a tow. Collectively, these tows are often woven into cloth. However, carbon fiber cloth can also conform to a specific shape when used with resin in a mold.

Carbon fiber fabric is lightweight but very strong, and it will last much longer than similar metal components under regular use conditions. In hot or cold environments, carbon fiber cloth exhibits considerably less expansion or contraction than aluminum or steel.

When processed with the proper resin, carbon fiber cloth is extremely resistant to corrosion and ultraviolet light. This versatile material also has high electrical conductivity.

How strong is carbon fiber?

Carbon fiber fabric has 5 times the strength of steel, and it is also twice as stiff. At the same time, carbon fiber fabric is very lightweight. These properties make carbon fiber fabric a preferred fabrication material for many applications.

What is carbon fiber used for?

Carbon fibers minimal weight, along with its high strength and stiffness, make it well suited to many applications. Its low thermal expansion coefficient is another well-known advantage.

When combined with the proper resin, carbon fiber composites are ideally suited for rigid, lightweight molded components. It is also ideal for structural and cosmetic uses.

Carbon fiber is often integral to construction of race cars and luxury vehicles. The commercial and military aircraft manufacturing industries also heavily utilize carbon fiber.

High-performance sailboats also incorporate carbon fiber throughout the construction process. Carbon components include boat hulls, masts, spinnaker poles, and battens.

What is twill weave carbon fiber?

Twill weave carbon fiber fabric always utilizes a 2x2, 4x4, or similar scheme that results in a diagonal pattern. To achieve this distinctive look, the tow passes over 2 intersecting warps and then passes under 2 warps.

Twill weave gives the carbon fiber fabric a looser, more pliable feel. These characteristics let the fabric better tolerate contours and curves.

What is plain weave carbon fiber?

Plain weave carbon fiber fabric resembles a symmetrical checkerboard. Also called 1x1 weave fabric, this cloth displays over/under patterned tows with tightly connected fibers. The fabric is considered very stable as it easily retains its weave angle and fiber dimensions.

However, the plain weave fabrics stability can also make it a poor choice for projects that require flexibility and intricate contours. Because it is easy to manipulate without causing unwelcome fabric distortions, plain weave fabric is a good choice for fabrication of tubes, flat sheets, and two-dimensional curves.

This basic 1x1 weave fabric is extremely popular in the aircraft, automotive, and boat-building industries. The fabric wets out very quickly, and it is quite easy to manipulate during the manufacturing process.

What is unidirectional carbon?

Unidirectional carbon fiber fabric contains fibers that all run in one direction and are parallel to each other. This non-woven fabric does not have any gaps between fibers, and there is not a cross-section weave that halves the fiber strength.

Use carbon fiber unidirectional fabric in areas that only require single-direction strength. To increase the strength factor, overlap the fabric at approximately a 45-degree angle. Do not use this fabric for components that require a high degree of strength in every direction.

What is carbon fiber tape used for?

Carbon fiber tape is typically used to strengthen a composite surface. As an added bonus, there is no need to cut down an entire sheet of fabric and perform a time-consuming layup operation.

Carbon fiber woven tape is often used as a composite reinforcement or to add structure to composite parts edges. It is also useful for lap joining and sleeve winding operations, along with graphite surfaces crack repairs. The aerospace, auto racing, and competition sailboat and powerboat racing industries utilize carbon fiber tape in varied applications.

Unidirectional carbon tape minimizes thickness and weight while increasing the tapes tensile strength and compression ability. The fibers follow a longitudinal direction, and a polyester fill thread keeps the bundles in place for easy usage.

Plain weave carbon fiber tape provides the same degree of strength in two directions. The tape is unlikely to fray, and has a good degree of fatigue resistance.

What kind of resin do you use with carbon fiber?

Technically, carbon fiber is compatible with both polyester and epoxy resins. However, polyester resin has several downsides that discourage its use with the expensive composite material.

First, budget-priced polyester resin has little flexibility, and will likely develop hard-to-repair spider cracks if you try to bend the substance. You will also need an increased quantity of resin, which adds undesirable weight and negates the carbon fibers lightweight benefits.

Polyester resin will eventually shrink and change the final product configuration. Finally, it will gradually turn yellow as it does not have any UV resistance.

Epoxy resin is a much better choice. Its flexibility enables the carbon fiber component to withstand considerable impact without breakage. Rather than developing a series of spider cracks, epoxy resin forms a single crack when its bending potential is exceeded.

Finally, epoxy resin displays a transparent finish, and also possesses UV resistance and non-shrinkage properties. These important advantages make epoxy resin an optimum choice for fabrication work. Together, carbon fiber cloth and resin provide the ingredients for quality composite construction.