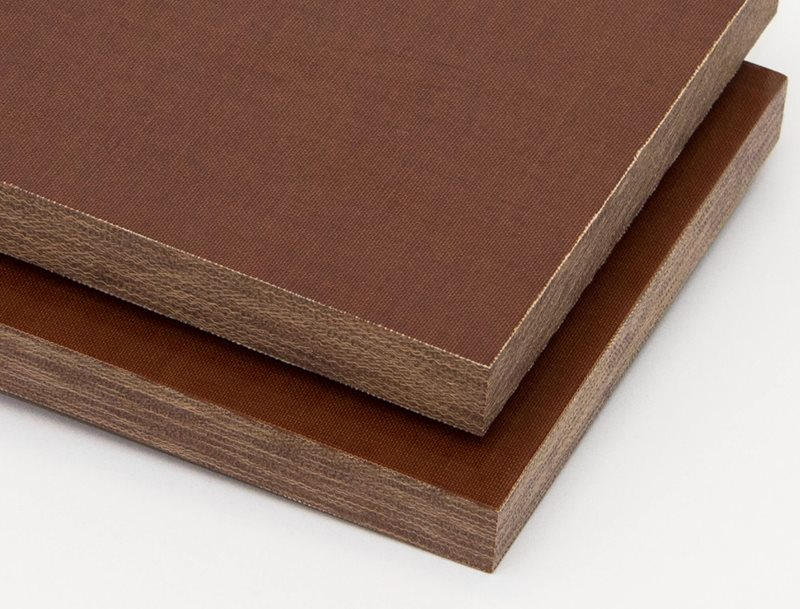

Phenolic plastic including canvas, linen, g10 epoxy phenolic resin sheet and specialized phenolic sheet grades have high strength and stiffness achieved through a reinforcement material.

What is Phenolic Plastic?

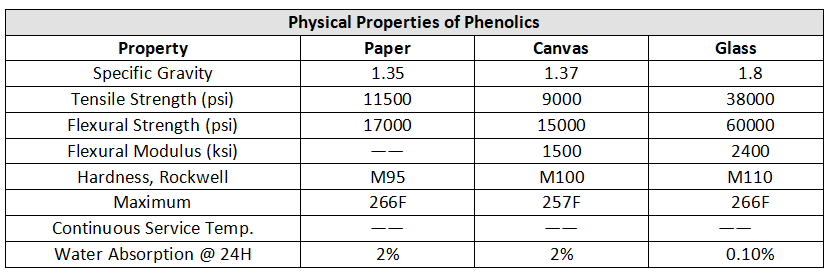

Phenolic machinable plastics are thermoset composite materials. They have the advantage of high strength and stiffness achieved through a reinforcement material.?Glass fiber or woven cotton with resins including phenolic or epoxy are blended to create sheet material. This process makes phenolics generally more cost effective than thermoplastics for the same application. These composites have varying properties depending on the resin-reinforcement materials used. Phenolic plastics carry nearly half the weight of aluminum, with a physical toughness that withstands abrasion, impact, and friction and material fatigue. Phenolic plastics are corrosion resistant to most chemicals and substances.

High tensile, compressive, flexural and impact strength make phenolic plastics the material of choice for many applications. Interstate Plastics offers various specialty grades of phenolic including "C" grade canvas sheet, "LE" grade sheet, paper "economy" grade sheet, and G-10 glass epoxy sheet. The insulating qualities of each grade - such as low dissipation factor and excellent dielectric strength-make phenolic plastics valuable for many precision electrical and electronic applications.

"C" Grade Canvas Phenolic:

Canvas "C" grade consists of a cotton canvas fabric and general-purpose phenolic resin. The product is easy to machine, known for high impact strength, and operates with less noise than metal. In addition, this material is not as abrasive as fiberglass alternatives when used in wear applications. Since it does not spark when struck, canvas phenolic can be used in explosion-proof environments. The material is commonly used to make gears, pulleys, rollers and guides. Canvas phenolic is a mechanical grade and does not have electrical properties comparable to the normative "C" grade. It can withstand temperatures up to 257F.

Linen "LE" Grade Phenolic:

Linen "LE" grade sheet is used where better machining is needed compared to that offered by canvas grades. This product consists of a fine-weave linen fabric and general-purpose phenolic resin. Besides easy machining, linen phenolic operates with less noise than metal. In addition, this physical material is not as abrasive as fiberglass alternatives when used in wear applications. Linen phenolic can be used in explosion-proof environments. It is suitable for smaller and more intricate shapes than those made with canvas phenolic, and is commonly used to make fine-tooth gears, pulleys, rollers, guides and other precision parts. Phenolic grade "LE" sheets will withstand up to 275F and has a moisture absorption rate of 1.3%.

Paper-masked "Economy" Grade Phenolic:

Paper "economy" grade is a paper-based laminate with low phenolic resin content. A non-nema economy grade, economy paper phenolic is typically hot punched for numerous low voltage electrical applications. Economy paper offers fair electric properties in dry conditions, but the product is not suitable for applications that require resistance to high humidity.

G-10 Glass Epoxy Sheet:

A light green material, G-10 glass epoxy sheet combines a woven glass fabric and an epoxy resin laminate that contains bromine. G10 provides consistent quality and good electrical properties under dry and humid conditions, as well as high flexural, impact, and bond strength at room temperatures. Due to a high mechanical strength, low water absorption and superior electrical characteristics, this product is suitable for a variety of structural, high humidity, and electrical insulation applications, which include terminal boards, lapping carriers, and disc and microelectronics polishing. It will withstand temperatures up to 284F and has a moisture absorption rate of 15%.

Strong, stiff, tough and durable

Excellent dielectric strength

Good machinability

Light weight

Heat and water resistant

Corrosion and chemical resistant

Good mechanical strength

Excellent wear properties

Good dimensional stability

Low moisture absorption

Excellent creep resistance

Phenolic Plastics Applications

Phenolic resins are found in myriad industrial products. Paper phenolics are used in manufacturing electrical components such as punch-through boards and household laminates. Glass phenolics are particularly well suited for use in the high speed bearing market. Snooker balls as well as balls from many table-based ball games are also made from phenol formaldehyde resin. The binding agent in normal (organic) brake pads, brake shoes and clutch disks are phenolic resin. Synthetic resin bonded paper, made from phenolic resin and paper, is used to make countertops. Phenolic resins are also used for making exterior plywood.

Printed circuit board substrates

Electrical insulators

Switch parts

Switch bases

Terminal boards

Insulating washers

Table tops, counter tops

Wear pads

Brake pads, brake shoes, clutch components

Wood and metal replacements