You may have heard of PEEK plastic, short for polyether ether ketone, a semi-crystalline thermoplastic polymer in the polyaryl ether ketone (PAEK) family. PEEK plastic has amazing properties that make it ideal for demanding applications in a variety of industries, such as aerospace, oil and gas, medical, food and beverage, and semiconductors. But you may also notice that PEEK plastic is more expensive than other common engineering plastics such as polyurethane, nylon and polycarbonate. Why is this?

In this article, we'll look at the factors that make PEEK plastics more expensive than other materials and compare them to other materials in terms of performance and value.

1.High-temperature synthesis

One of the main reasons why PEEK plastic is more expensive than other materials is the complex high temperature synthesis process required to manufacture it. PEEK plastic is produced by stepwise polymerisation of bisphenol salts and difluorobenzophenone in a polar non-protic solvent at around 300°C. This reaction is difficult to control and requires special equipment and catalysts. The reaction produces a PEEK resin with a high molecular weight and high crystallinity, which gives it excellent mechanical and thermal properties. However, this also means that PEEK resins are difficult to melt and process into the final product.

2.Supply vs. demand

Another factor is the limited supply and high demand for PEEK resin. As PEEK plastic is a relatively new material, first made in the late 1970s, a relatively short time ago, there are few manufacturers able to produce it on a large scale. The global production capacity for PEEK resin is estimated to be around 10,000 tonnes per year, which is much lower than the production of other engineering plastics that have been around for a longer period of time. In addition, demand for PEEK plastic is growing rapidly due to its increasing popularity in a variety of industries requiring high performance and durability. This has created an imbalance between supply and demand, driving up the price of PEEK resin.

3.Process technology requirements

The third factor is the specialist equipment and expertise required to process and fabricate PEEK plastics into the final product. Because of the high melting point of PEEK plastics, around 343°C, and the high glass transition temperature of around 143°C, high temperature injection moulding machines or extrusion machines are required to mould them into the required shape. These machines are more expensive and energy consuming than conventional machines. On both sides, PEEK plastic has a strong tendency to degrade or oxidise when exposed to oxygen or moisture at high temperatures, which means it needs to be processed in an inert atmosphere or with special additives. In addition, PEEK plastic has high abrasion resistance and hardness, which makes it difficult to cut or machine with standard tools. Processing and manufacturing PEEK plastics therefore requires skilled operators and engineers who have experience and knowledge of handling this material.

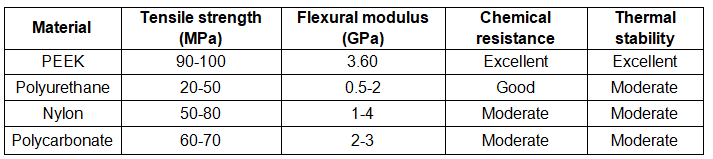

Now that we have discussed the factors that make PEEK plastic more expensive than other materials, let us compare the parameters of PEEK plastic with other common engineering plastics in terms of performance. The following table shows the key properties of different engineering plastics.

As you can see in this chart, PEEK plastic, despite its higher cost, stands out for its excellent strength, chemical resistance, and thermal stability, making it suitable for demanding applications. It is used to produce components like bearings, seals, valves, and pumps that perform reliably under high temperatures and pressures while resisting corrosion and wear.

In the medical field, PEEK is valued for its biocompatibility and ability to withstand autoclave sterilization, making it ideal for implants, instruments, and devices. In food processing, it resists harsh cleaning chemicals and prevents bacterial growth. Additionally, PEEK is used in semiconductor machinery for its ability to handle high vacuum, radiation, and electrical insulation requirements.

In summary, PEEK plastic is more expensive than other materials because of its complex and high temperature synthesis process, the limited supply and high demand for PEEK resin, and the specialised equipment and expertise required to process and manufacture PEEK plastic. However, these factors also make PEEK plastics ideal for demanding applications that require high performance and durability. As a result, PEEK plastics can offer high value and benefit to those looking for high performance engineering plastics that can more than meet project requirements.

If you would like to find out more about PEEK plastics or to purchase PEEK products, please contact us at sales@weitengroup.com, wwww.weitengroup.com.