Definition:

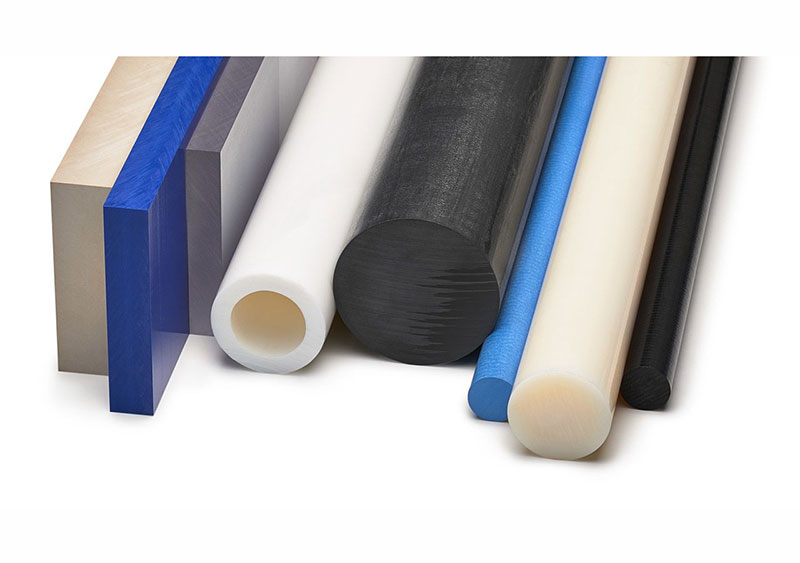

Engineering plastics, also known as technical plastics or high-performance plastics, are a class of polymers that exhibit superior mechanical, thermal, chemical, and electrical properties compared to commodity plastics. These materials are designed to withstand harsh environmental conditions and demanding engineering applications.

Importance:

Engineering plastics play a crucial role in various industries due to their exceptional properties and versatility. They are preferred for applications where traditional materials like metals or commodity plastics may not meet the required performance criteria. The importance of engineering plastics lies in their ability to provide lightweight, durable, and cost-effective solutions for a wide range of engineering challenges.

Uses:

Engineering plastics find applications across numerous industries, including automotive, aerospace, electronics, healthcare, construction, and consumer goods. Common uses include:

1.Automotive components: Engine components, interior trim, exterior body panels, and electrical connectors.

2.Electrical and electronic applications: Insulating materials, connectors, circuit boards, and housings for electronic devices.

3.Aerospace components: Interior components, structural parts, and aircraft interiors.

4.Medical devices: Surgical instruments, implantable devices, and medical equipment housings.

5.Industrial machinery: Gears, bearings, seals, rollers, and wear-resistant components.

6.Consumer goods: Sporting equipment, appliances, toys, and packaging materials.

Properties:

Engineering plastics exhibit a wide range of properties depending on their chemical composition and molecular structure. Some common properties include:

1.Mechanical properties: High strength, stiffness, toughness, and impact resistance.

2.Thermal properties: High heat resistance, thermal stability, and low coefficient of thermal expansion.

3.Chemical resistance: Resistance to acids, bases, solvents, oils, and other chemicals.

4.Electrical properties: Insulating properties, high dielectric strength, and low electrical conductivity.

5.Dimensional stability: Low creep, minimal moisture absorption, and tight tolerance control.

6.Flame resistance: Self-extinguishing or flame-retardant properties in some formulations.

7.Weatherability: Resistance to UV radiation, moisture, and outdoor exposure.

Types:

There are various types of engineering plastics, each with unique properties and applications. Some common types include:

1.Polyamide (Nylon): Excellent strength, toughness, and abrasion resistance.

2.Polycarbonate (PC): High impact resistance, optical clarity, and heat resistance.

3.Polyoxymethylene (POM or Acetal): Low friction, high stiffness, and excellent dimensional stability.

4.Polyethylene terephthalate (PET): High strength, stiffness, and chemical resistance.

5.Polyetheretherketone (PEEK): High temperature resistance, chemical resistance, and mechanical strength.

6.Polyphenylene sulfide (PPS): Excellent chemical resistance, high temperature stability, and dimensional stability.

7.Polyetherimide (PEI or Ultem): High heat resistance, flame retardancy, and electrical properties.

These are just a few examples, and there are many other engineering plastics available, each tailored to specific application requirements.

In summary, engineering plastics are advanced materials with superior properties that make them indispensable in a wide range of industries and applications. Their versatility, durability, and performance make them essential for modern engineering and manufacturing processes.