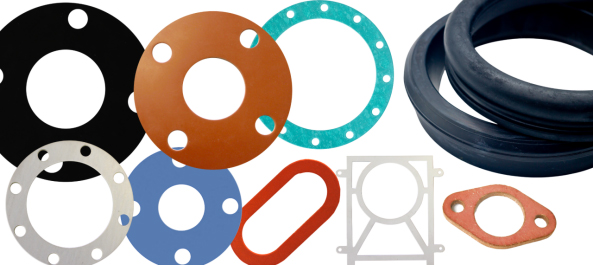

Rubber is one of the most common materials used to produce gaskets and seals. Choosing the correct rubber for an application can be a difficult and time-consuming process due to the multitude of different rubber composite materials available.

We would always recommend talking to our technical team for clear advice about your specific requirements, but we hope this brief guide provides general information to assist you in choosing the appropriate rubber gasket material.

1. Determine the Operating Conditions:

Temperature Range: Consider the minimum and maximum temperatures the gasket will encounter during operation.

Pressure Range: Determine the pressure levels the gasket needs to withstand.

Chemical Compatibility: Identify the chemicals or fluids the gasket will come into contact with and ensure the material is resistant to them.

Environmental Factors: Assess the exposure to UV radiation, ozone, weathering, and other environmental conditions.

2. Understand Gasket Material Types:

Rubber Gasket Materials

Nitrile: Suitable for applications with oils, fuels, and other petroleum-based fluids. Good resistance to compression set and abrasion.

Neoprene: Exhibits good resistance to weathering, ozone, and moderate oil resistance. Suitable for outdoor applications.

EPDM: Excellent weather resistance, ozone resistance, and good chemical compatibility. Often used for outdoor, automotive or food processing applications. More about EPDM Gaskets

Silicone: Wide temperature range (-60°C to 230°C), excellent flexibility, and resistance to UV and ozone. Suitable for food-grade and high-temperature applications.

Viton: Exceptional chemical resistance, high-temperature resistance, and suitable for applications with fuels, oils, and harsh chemicals.

Natural Rubber: Good resilience, abrasion resistance, and elasticity. Not recommended for exposure to oils, fuels, or ozone.

Hypalon: Completely ozone and UV resistant with excellent recovery and stability properties when used in harsh environmental conditions.

Butyl: The blend of isobutylene and isoprene forms an impermeable seal often used in processing gases. It also has excellent thermal and anti-ageing properties.

Insertion: Rubber and styrene-butadiene composite with a fabric reinforcement is used in many common sealing applications where water or mild chemicals are a factor.

More information on Rubber Gasket Materials and our manufacturing processes

3. Consider Specific Application Factors:

Food and Beverage: Choose WRAS and FDA-compliant materials such as EPDM or silicone for gaskets in food and beverage processing.

High-Temperature Applications: Opt for materials like silicone or viton capable of withstanding elevated temperatures.

Chemical Resistance: Select gasket materials that offer resistance to specific chemicals encountered in your application.

Electrical Insulation: Materials with high dielectric strength, such as silicone, can be suitable for electrical enclosure gaskets.

Sealing Performance: Evaluate the material's compression set, flexibility, and ability to maintain a seal over time.