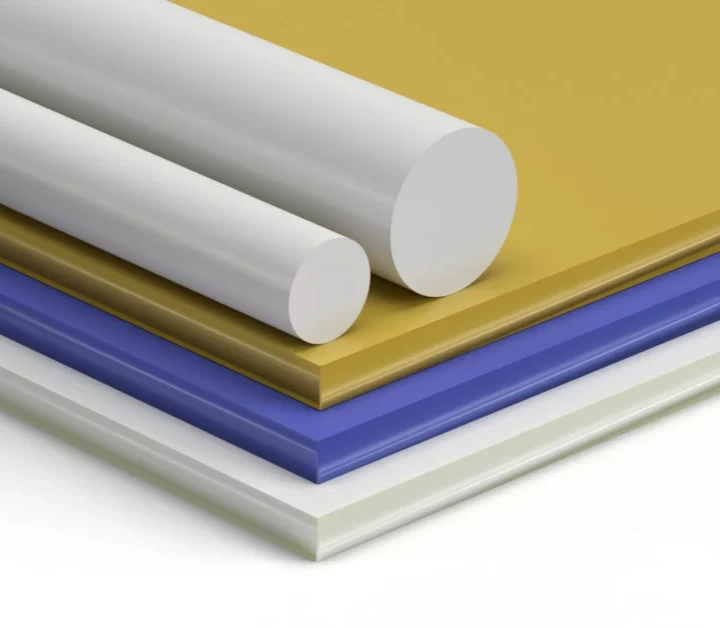

UHMWPE is a high-performance engineering plastic with a higher molecular weight than conventional polyethylene, usually between several million and tens of millions. Due to its unique molecular structure, UHMWPE has excellent physical properties, especially in terms of wear resistance, impact resistance, chemical resistance and self-lubrication. It is widely used in machinery, medical, aerospace, military and other fields, and is a high-performance material that can withstand extreme environmental conditions.

Core characteristics of UHMWPE

1.UHMWPE has a very low coefficient of friction and excellent wear resistance, making it one of the most wear-resistant materials of all plastics. In high-friction environments, it can significantly reduce wear and extend the service life of parts.

2.Due to its low coefficient of friction, UHMWPE is often used as a self-lubricating material, reducing the need for external lubricants, and is widely used in sliding parts such as bearings, sliders and conveyor belts.

3.UHMWPE has excellent resistance to most chemicals, including acids, alkalis, oils and solvents, which makes it widely used in chemical processing and oil and gas industries.

UHMWPE not only has extremely high tensile strength and bending strength, but also has high rigidity, which makes it more stable when subjected to external forces and suitable for high-load applications.

4.UHMWPE can maintain its toughness and strength at extremely low temperatures, and even maintain good performance at low temperatures of -200°C, which is very suitable for applications in extremely cold environments.

Main application areas of UHMWPE

1.In the industrial field, UHMWPE is widely used to manufacture wear-resistant and impact-resistant parts. The low friction performance of UHMWPE makes it an ideal choice for conveying systems and mechanical devices. It can extend the service life of equipment. In the mines, mining and oil industries, it is used for wear-resistant linings in devices to prevent equipment from being damaged.

2.UHMWPE materials play an important role in military and protective equipment due to their excellent strength and impact resistance. They are used to make lightweight bulletproof materials and are widely used in bulletproof vests and protective shields for military and police, using their impact resistance and cut resistance to protect personnel from injury.

3.UHMWPE is widely used in the aerospace field due to its extremely high strength and impact resistance, which can effectively protect equipment from extreme environments. In the moving parts of aircraft, UHMWPE is often used as guide rails and sliders to reduce friction and wear.

Contact us

If you would like to find out more about UHMWPE or to purchase UHMWPE, Please contact us for pricing and conditions. We can provide detailed information and tailor a solution to your needs.

EMAIL:sales@weitengroup.com

MOBILE:86-18561739639