Characteristics and Advantages

The demand for Spiral Wound Gaskets in the oil and gas industry is showing an optimistic growth trend. Our carefully designed Spiral Wound Gaskets have the highest quality flexibility and recovery to retain heat under fluctuating temperatures and high pressures. As one of the best spiral wound gasket manufacturers in China,WEITENG Gasket has decided to provide you with a clear initial guide about gaskets.

What is Spiral Wound Gasket?

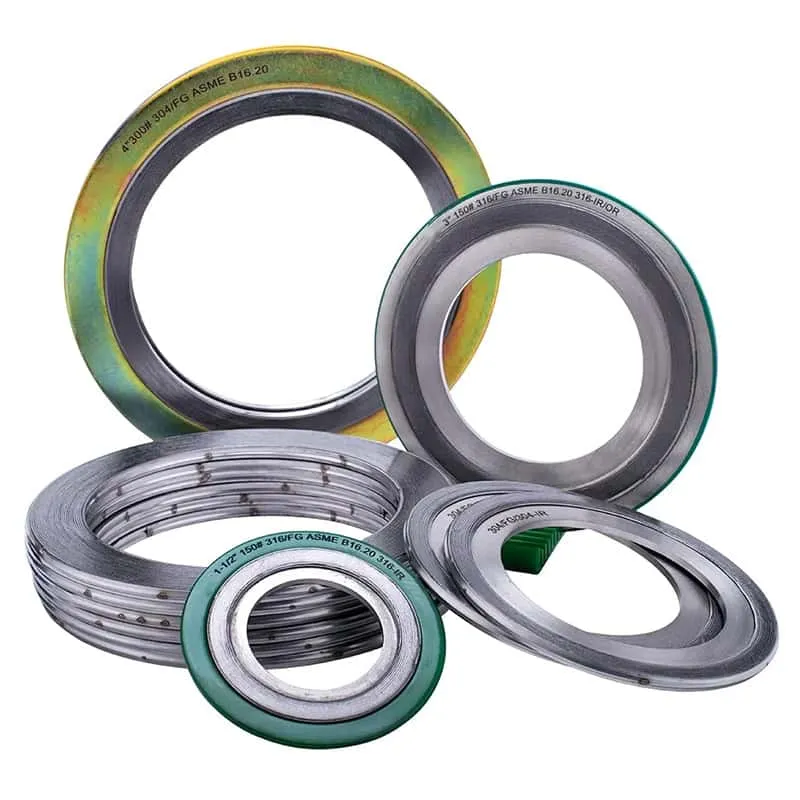

Spiral wound gasket is a spiral-shaped wound, interposing the layers of non-metallic tape. The gasket is made up of graphite or PTFE, stainless steel, and mica. The Spiral Wound Gaskets are suitable for moderate and critical operating conditions.

The Spiral wound gasket has high resistance property in comparison with other metal and asbestos type gaskets. Industries such as chemical and petrochemical sectors, oil and gas, refinery, nuclear power stations, device construction, steam generation use gaskets. It can be used elsewhere; as there is a need to manage extreme temperatures and high pressures safely.

The Characteristics of Spiral Wound Gaskets

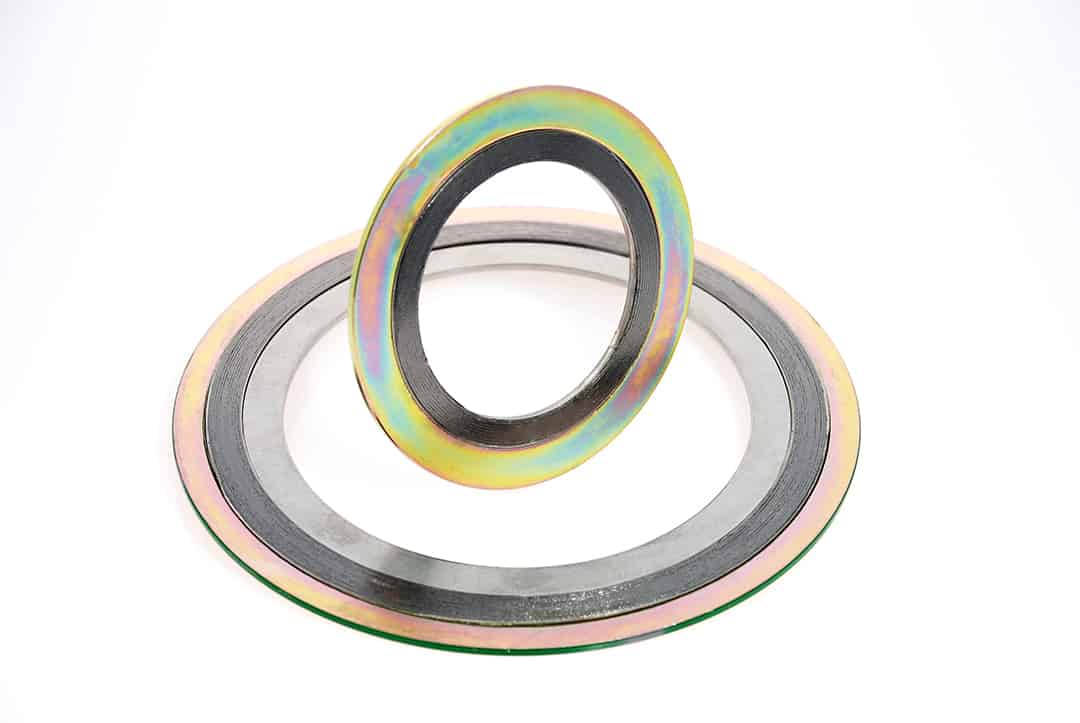

Spiral Wound gasket is composed of three layers, external ring, windings, and inner ring. These components are used to prevent contamination,product attacks in the pipeline joints and minimize the risk of material creep from over-tightening.

The external ring is made from stainless steel, Nickel, and carbon steel. It provides accuracy in centering the gasket on the flange face and acts as a compression limiter. The compression (ability) of the gasket can be controlled to some extent by varying the density. It is widely used in the Petrochemical and refinery sectors.

The inner ring acts as an additional compression stop and prevents the gasket from flange erosion and heat. It has a higher resistance to thermal shocks. The inner ring is suitable to use with a flat face and raised face flange, which also makes it an ideal gasket for vacuum services.

Advantages of Spiral Wound Gasket

The Spiral Wound Gaskets are available in different styles and shapes. The spiral wound design is the most popular gasket. Here are some benefits of using Spiral Wound Gaskets.

Gaskets are designed to handle temperaturechanges and high pressure ensuring secure sealing.

The fillers provide excellent sealing, while metal strips act as structural strength and useful for quick and easy recovery.

Spiral Wound Gaskets can be used for multiple purposes like leak prevention, mounting, padding, sealing, reduce vibrations, and for protection against environmental contaminants.

It offers efficiency for various operating conditions and easy to install ,Works effectively on corrosive environments with less clamping forces than solid gaskets , Spiral wound element provides additional security and prevents blow-out.

So, do you find these Spiral Wound Gaskets beneficial?

WEITENG Gasket offers a wide range of Spiral Wound Gaskets to optimize operational reliability. To learn more, please visit https://www.weitengroup.com/ For any questions regarding Spiral Wound Gaskets, please send an email to export@weitengroup.com or call us at +86 13370996824 .